Weifang Shengtai Pharmaceutical Co., Ltd. is a core enterprise of Shengtai Group, established in February 1999 and listed in the United States in May 2007. The total assets are 2 billion yuan, mainly engaged in the research and development, manufacturing, and sales of raw materials such as starch and glucose, as well as pharmaceutical excipients. The annual production of starch series products is 500000 tons and glucose series products is 300000 tons. The product is widely used in industries such as medicine, food, papermaking, fine chemicals, and biotechnology, and is sold to 30 provinces, municipalities, and autonomous regions in China, and exported to more than 70 countries and regions. Among them, medicinal grade glucose is a "famous brand" product in Shandong Province, with a domestic market share of over 70%. Has been awarded honors such as "Key Leading Enterprise in Agricultural Industrialization" and "Invisible Champion Enterprise" in Shandong Province, "Top 100 Industrial Enterprises", "Top 50 Agricultural Leading Enterprises", and "Intelligent Manufacturing Benchmark Enterprise" in Weifang City.

The current sewage treatment capacity of Weifang Shengtai Pharmaceutical Co., Ltd. is 4200m ?/ d. They are starch wastewater, glucose wastewater, modified starch wastewater, and feed additive wastewater, which have complex water quality components and high treatment difficulty. According to on-site inspection, Shanghai Wending Environmental Protection Technology Co., Ltd. has treated 5800m?/ D of water after the renovation to achieve expansion and renovation .

Project difficulties:

1. The working conditions are complex, and the difficulty of renovation construction is high;

2. The available land area for renovation is small, and the renovation will not stop production;

Project features:

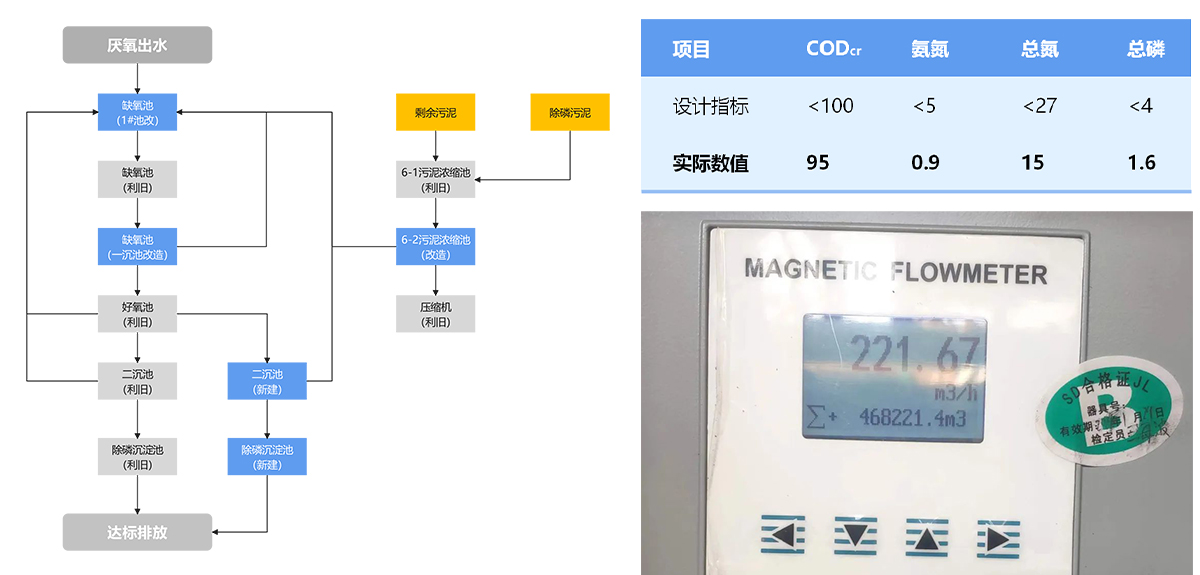

1. Transform the regulating tank and pre acidification tank into an anoxic tank to improve the system's denitrification treatment capacity.

2. The first sedimentation tank will be transformed into an aerobic tank, and a new second sedimentation tank will be built to increase the treatment capacity of the biochemical system.

3. Build a new phosphorus removal sedimentation tank to improve the system's TP degradation capacity.

Project achievements:

1. The existing system renovation has been successfully completed while the system is in operation.

2. The processing capacity ranges from 4200m ?/ Elevated to 5800m ?/ D.

3. The actual operating data is better than the design indicators (unit: mg/L):