Company news

Suzhou Dazhi

Wastewater Zero Discharge Project

Suzhou Dazhi Information Accessories Co., Ltd.

Ju Teng International Holdings Co., Ltd. (Ju Teng), established in 2000, has more than 40,000 employees. It is a professional manufacturer of 3C supporting products, with production bases throughout East China, South China, West China and Taiwan. Well-known brand customers such as HP, Dell, Acer, Apple, Sony, Toshiba, etc. are Ju Teng's long-term cooperation customers; and in terms of domestic OEM/ODM customers, they are among the top five global notebook computer assembly OEM customers, such as Quanta , Compal, Wistron, Inventec, Asus, etc. are all important customers of the company. Ju Teng was listed on the main board of the Hong Kong Stock Exchange in 2005 (stock code: 03336.HK) and listed on the Taiwan Stock Exchange in the form of Taiwan Depository Receipts (stock code: 9136.TW) in 2009.

Suzhou Dazhi Information Accessories Co., Ltd. is affiliated to Ju Teng International and is an important processing, assembly and manufacturing base of Ju Teng International. Suzhou Dazhi is located in the Taihu Lake Basin, and has extremely high requirements for environmental protection and energy conservation. For this reason, the company takes the initiative to undertake social and environmental responsibilities, and strives to produce nearly zero discharge (ZLD) of sewage.

Project implementation

This project is mainly sewage from anodizing lines, which has the characteristics of strong acidity, many types of components, and complex components. Therefore, how to effectively remove pollutants, achieve near-zero discharge of production sewage, realize water resources reuse and recovery of valuable materials in water bodies, This is the main technical difficulty of this project.

Based on the company's technical accumulation and industry experience, the environmental protection technical team of Winner conducted in-depth research and analysis on the composition and characteristics of the wastewater in each workshop, and confirmed the use of physicochemical + biochemical treatment, membrane separation and evaporation crystallization processes, and finally formed a complete A zero-discharge solution for production sewage, and the goal of reducing hazardous waste such as emulsions by more than 80%.

3D design drawing of membrane separation in water system↑

Craftsmanship, Technology and Innovation

The technological innovation points are as follows:

(1) Using the combination of Winner high-efficiency air flotation technology and biochemical process to remove refractory organic pollutants in sewage;

(2) Using the full-membrane separation technology to reuse the water resources and material resources of the sewage system and reuse them for production;

(3) The concentrated brine is separated through the energy-saving MVR evaporation device to achieve the goal of "zero discharge" of production sewage;

(4) Design skid-mounted low-temperature vacuum evaporator/ceramic membrane process equipment to achieve a substantial reduction in the treatment of hazardous waste with a high concentration of CNC emulsified cutting waste liquid of more than 80%.

UF ultrafiltration membrane system↑

RO membrane separation and concentration system↑

Sludge reduction device↑

Project Management Delivery

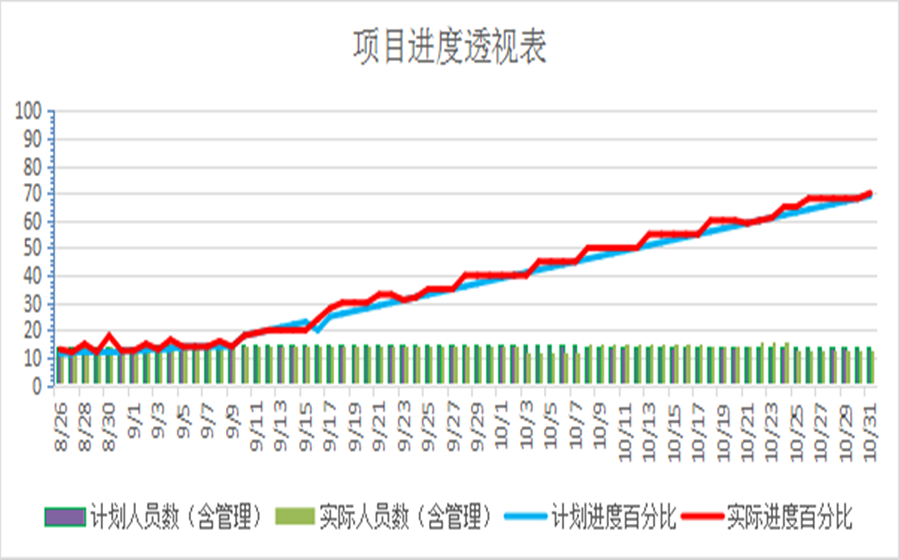

In July 2021, the winner environmental protection project team entered the project site of Suzhou Dazhi Information Accessories Co., Ltd. Under the pressure of tight schedule and heavy tasks, the company rationally organized human resources, the project team strictly controlled the project progress as planned, and abide by the safety and quality goals. As summarized by the project-related collaboration and management personnel: the Suzhou Dazhi project has achieved the whole process from design, procurement to implementation and delivery, reflecting Winner's strict control standards for safety and quality.

During the construction of the project, Winner Environmental Protection has always maintained good communication with the owner. In the daily morning meeting, work plans and tasks will be arranged, and pre-work safety education will be carried out. On the construction site, regularly inspect the compliance of labor insurance wearing and operation, and the standardization of equipment installation, and hold periodic project summary meetings on a regular basis to grasp the construction progress in real time and the whole process to ensure the quality of the project progress. During the implementation of the project, the daily plan, weekly plan, construction schedule and other related documents are open and transparent to the owner, and the construction adjustment plan is made according to the owner's production requirements.

The Suzhou Dazhi project entered the site on July 15, 2021 and completed the system commissioning on October 31. During this period, Winner Environmental Protection's measures in project safety management, technical operation, important node control and other aspects, as well as the strong execution force of the project team, were all obtained. Unanimously praised by the owners.

For the past 20 years, Winner Environmental Protection has been committed to solving the difficult industrial waste water pollution problem in China, with the vision of making customers a respected enterprise by the society, and empowering China's environmental protection cause with knowledge and innovation.