Aurijin Technology Co., Ltd. is a large-scale specialized metal packaging enterprise that integrates metal can making, metal printing, bottom cover production, easy to pull cover manufacturing, and new product research and development. For a long time, Aurijin Cans has been committed to revitalizing China's metal container manufacturing industry and creating international quality metal packaging. We mainly provide customers with the production of packaging products for various types of food, beverages, canned goods, seasonings, beer, dairy products, and other products. At the same time, we can provide comprehensive packaging solutions including high-tech packaging design, printing, manufacturing, and comprehensive customer service.

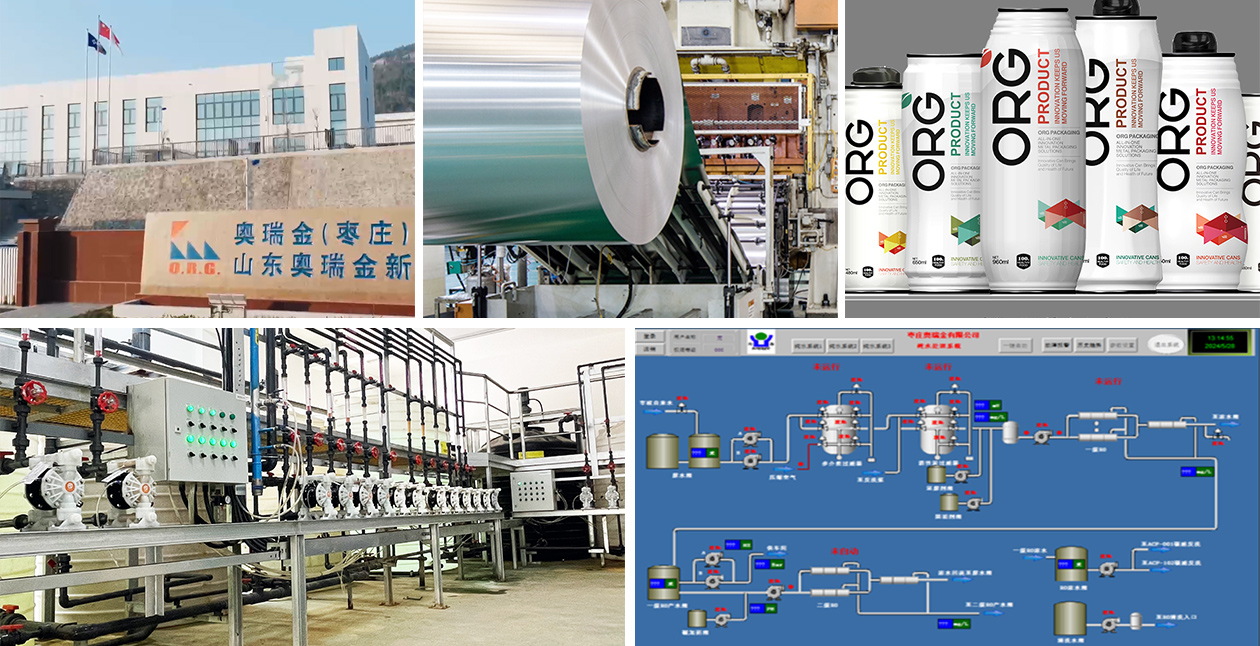

Aoruijin (Zaozhuang) Packaging Co., Ltd. and Shandong Aoruijin New Energy Co., Ltd. are wholly-owned subsidiaries of Aoruijin Technology Co., Ltd. They settled in Xuecheng District, Zaozhuang City in 2021, covering a total area of 97.8 acres. The company's main products are two-piece aluminum cans, which can produce 330ml, 500ml, Slim, Stubby, and Sleek can types; The company's main customers are well-known brands such as Qingdao Beer, Coca Cola, Jiaduobao, Dongpeng Special Drink, Yizhibi, and Zhanma. The total investment for the first phase of the project is about 360 million yuan, with an annual output of nearly 900 million units and an estimated annual output value of 414 million yuan.

Aurijin has always adhered to the "sustainable packaging strategy" and has been extremely practical in packaging technology. Compared with traditional metal packaging technology, the film coated iron technology developed by Aurijin has the natural advantages of low-carbon, environmental protection, and green. The expansion plan for building a factory in Zaozhuang is an inevitable choice in line with Shandong's future green and low-carbon transformation and development strategy. Aoruijin (Zaozhuang) Co., Ltd. has an annual production capacity of 900 million cans of coated iron cans, and Shandong Aoruijin New Energy Co., Ltd. has a production capacity of 10 million sets of new energy battery structural components, effectively combining "packaging+new industrialization" industry innovation.

The reuse rate of acid and aluminum containing wastewater in production has reached over 85%, with a reuse water volume of 35m ?/h. The DI water replenishment in the production workshop is only 5m ?/h. Most of the water in the canned production line is recycled, saving water resources and greatly reducing the unit consumption of water in green factory products and the consumption of chemicals in sewage treatment. The designed treatment capacity of the new sewage station is 700m ?/d, which meets the drainage requirements of the production line. The water quality of the discharged water meets the Class A standard of the Water Quality Standards for Sewage Discharged into Urban Sewers (GB/T31962-2015).

Project technical features

The acid and aluminum containing wastewater in green production manufacturing adopts online recycling and treatment processes to meet the requirements of reducing production line wastewater and resource recycling.

Regarding the fluoride pollution concentration of 100-200mg/L in the production wastewater of aluminum two-piece cans, it is difficult to achieve the discharge requirement of less than 10mg/L using the calcium method alone. Therefore, it is necessary to select appropriate fluoride removal agents and processes in combination to reduce fluoride pollution.

When cleaning the tank solution on the production line, the emulsion wastewater and the stretching workshop pit wastewater have high oil content. Separate collection and oil separation of this batch of wastewater can avoid impact on the biochemical system.

By adding remote monitoring system ports, operational data can be remotely transmitted to computers and mobile apps, enhancing the ability to meet wastewater treatment standards and achieve lean wastewater management.

Project achievements

The project has successfully completed acceptance, and the effluent water quality is stable and meets the standards. The discharged water quality meets the A-level standard of the "Water Quality Standards for Sewage Discharged into Urban Sewers" (GB/T31962-2015) and the sewage plant takeover standard.

Assist Aurijin (Zaozhuang) Packaging Co., Ltd. in ESG environmental governance strategy, practice green factory wastewater resource utilization and reduction recycling.

The resource utilization technology for aluminum two-piece tank production wastewater has achieved effective combination of water-saving, sewage treatment, and comprehensive utilization of water resources in the two-piece tank industry, improving the water efficiency of the industry. Efficient biological treatment technology can adapt to the wastewater environment of two tanks, with effluent COD ≤ 50mg/L and a removal rate of over 95%. The ultra-low fluoride pollution control technology can control fluoride ions below 20mg/L.

This project comprehensively applies the key technology of the comprehensive utilization of aluminum two-piece can production water system from Wending Environmental Protection, to assist the green, energy-saving, and low-carbon production of the Aurijin canning production line.